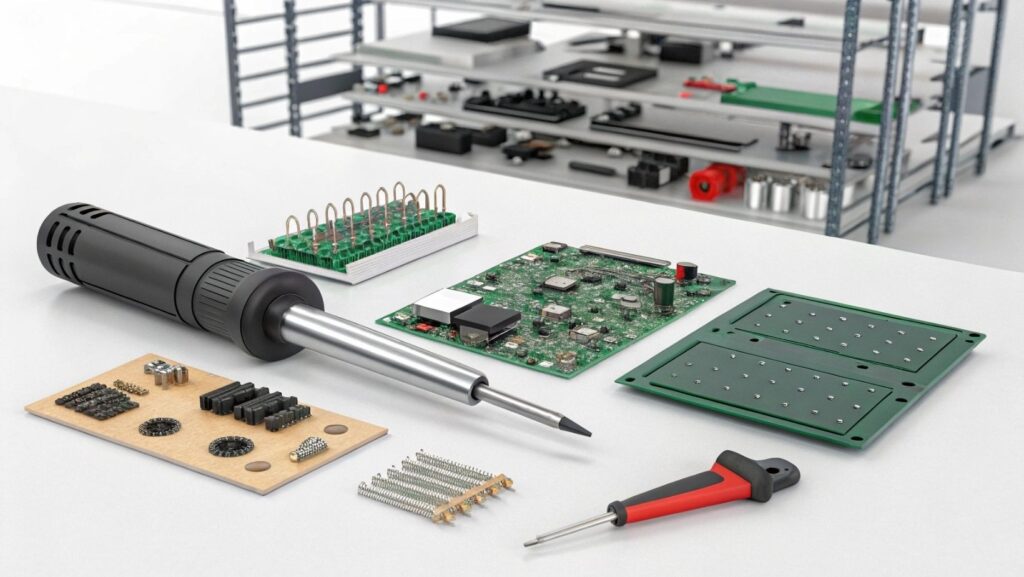

If you work in electronics manufacturing, you’ve likely felt the pressure from growing PCB assembly expenses. Your bottom line depends on finding ways to cut these costs without sacrificing quality, whether your company is established and trying to increase margins or a startup introducing its first product. The good news? Several techniques can drastically reduce your PCB assembly expenses while still keeping the dependability and performance your customers demand.

Good Design Choices Change Everything

One of the most effective strategies to cut assembly expenses starts in the design stage. Designing with manufacturability in mind will help you set yourself up for major savings down the line.

Standardize Components

Consider grouping your component selections for several projects into standards. Common component use not only lowers material costs through volume buying but also streamlines inventory control and lowers the possibility of component shortages.

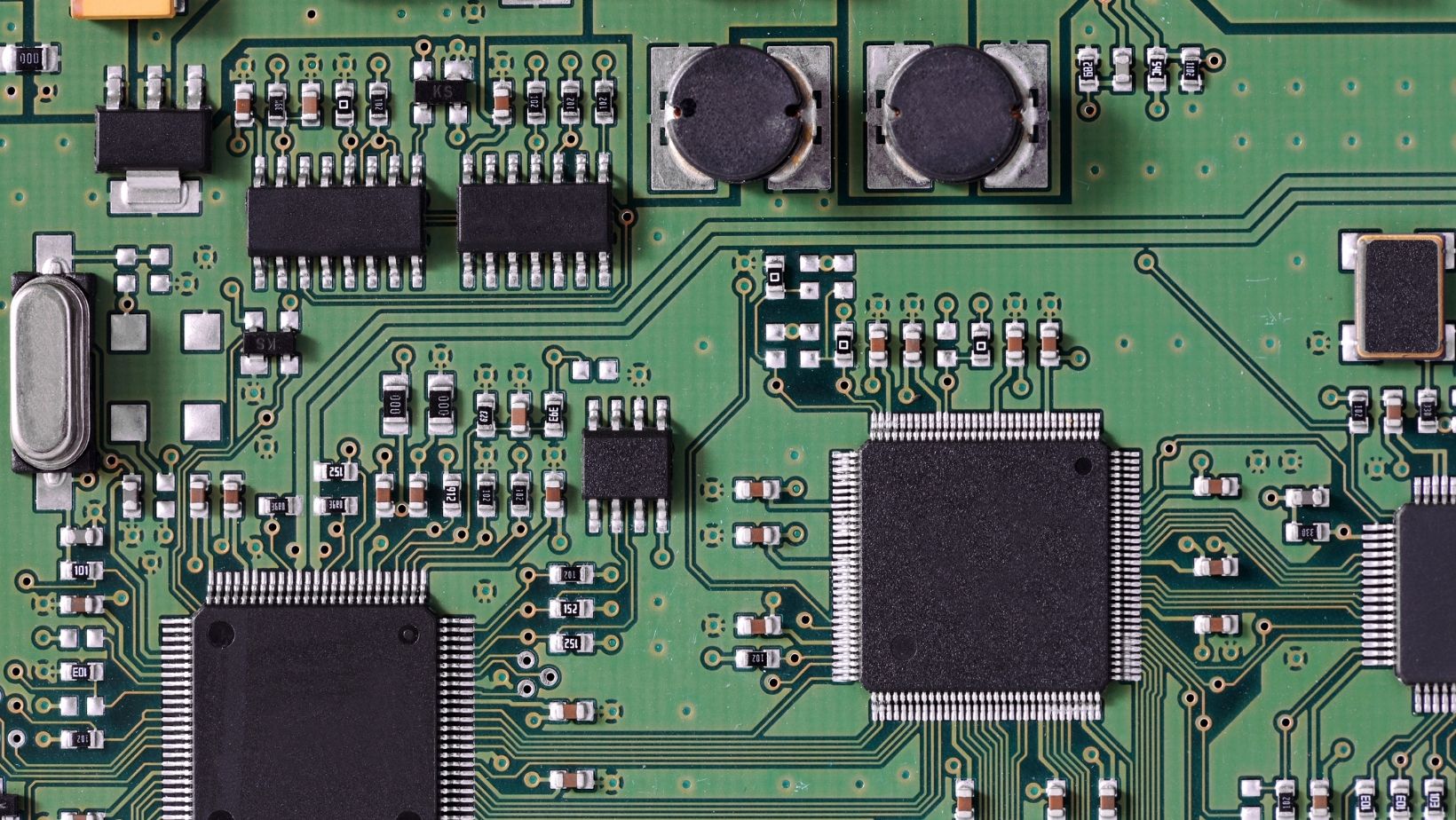

Optimize Layout and Tolerances

Component location and orientation are still critical design issues. Grouping like components and maintaining constant orientations can greatly reduce assembly time. This leads to faster throughput and reduced labor costs because fewer machine setup changes are needed during production. Furthermore, avoiding complex geometries and overly strict tolerances will help prevent expensive rework and yield problems.

Improve Your Component-Choosing Plan

Your component selections greatly affect long-term manufacturing efficiency as well as immediate costs.

Prioritize Availability and Resilience

Choose easily available components from several vendors whenever possible. This strategy guarantees not only competitive prices but also supply chain resilience. Steer clear of imported or recently introduced products that demand premium prices, particularly if more basic solutions will satisfy your needs.

Consider Total Cost of Ownership

Please consider the entire cost of ownership when selecting parts. Although a less expensive component could first seem appealing, it could wind up costing more over time if it needs special handling, has low yield rates, or calls for further testing. Work closely with your assembly partner to find which parts fit their procedures and tools.

Use Time and Volume Advantages

Volume plays a crucial role in reducing PCB assembly costs.

Leverage Higher Quantities

Usually, higher quantities translate into lower per-unit costs because of material buying power and amortizing setup costs. To reach better pricing levels, think about grouping orders depending on your production schedule. The cost savings might justify the extra inventory carrying expenses, even if you don’t need all the units right now.

Strategic Order Timing

Timing your orders deliberately can also result in notable savings. Often, assembly houses have better rates during their slower times. Planning your manufacturing cycles to coincide with these times will help you negotiate better prices. Longer lead times also allow your assembly partner more scheduling flexibility, which they usually value in terms of pricing.

Create Strong Relationships with Suppliers

Building close ties with your PCB assembly partners will open savings beyond just nominal volume discounts. Working closely with your suppliers helps them better grasp your needs and may enable recommendations for improvements you might not have thought of.  They might suggest design changes that cut assembly complexity, recommend substitute components with better value, or offer analysis of market trends that might impact your expenses.

They might suggest design changes that cut assembly complexity, recommend substitute components with better value, or offer analysis of market trends that might impact your expenses.

Consider focusing on building relationships with a select group of reliable vendors rather than constantly seeking the lowest quote. Better service, priority scheduling during peak times, and access to preferred pricing usually follow from long-term alliances. Seeing you as a valued, long-term customer increases your suppliers’ likelihood of investing in knowledge of your particular needs.

Accept the Design for Testability

Although it would seem contradictory, investing in appropriate testing during the design stage can greatly lower total assembly costs. Although built-in test points, boundary scan capabilities, and other testability features may have modest upfront costs, they can significantly reduce later debugging and rework costs. Early assembly process problems are usually far less expensive to address than those found during final testing or, worse, in the field.

Think about putting in-circuit testing (ICT) and automated optical inspection (AOI) requirements into your design. Early assembly flaws found by these testing techniques help reduce the need for costly handmade troubleshooting and rework. The secret is to strike a mix between the possible savings from lower rework and better yield rates against the cost of extra test features.

Simplify Your Need for Quality

While maintaining quality is crucial, it’s important to assess if all your requirements for it are truly necessary. Over-specification can cause needless expenses. Review your testing needs, cosmetic standards, and documentation requirements to make sure they match your real needs instead of depending on antiquated or overly conservative guidelines.

Work with your assembly partner to learn how varying quality levels would affect costs. Occasionally, a somewhat lowered cosmetic standard or another testing method can save a lot of money without compromising functionality. The aim is to reach the quality level your application really calls for without paying for pointless premium criteria.

Consider Your Regional Manufacturing Options

Geographic location significantly influences the costs of PCB assembly. Although offshore manufacturing has always had the lowest prices, other factors, including shipping costs, lead times, and communication difficulties, must be accounted for even as the difference is closing. Analyze the whole cost of ownership—including inventory carrying expenses, logistics, and the value of shorter communication cycles and faster response times.

Nearshore or regional manufacturing options offer many businesses the ideal mix of cost and convenience. Companies like OurPCB have demonstrated that competitive pricing doesn’t always require going to the other side of the world. At times, the savings from logistics, reduced inventory requirements, and improved communication outweigh the slightly higher manufacturing costs.

Result

Reducing PCB assembly costs calls for a comprehensive strategy including supplier relationships, quality standards, and initial design decisions, among other factors. The secret is to see cost-cutting as an ongoing process including constant evaluation and optimization rather than as a one-time activity. Start by using the techniques that fit your present circumstances and progressively increase your efforts at cost control as you develop confidence and experience.

Recall that the least expensive solution isn’t usually the best value. Emphasize keeping the quality and dependability your clients demand while maximizing the total cost of ownership. For your company, which cost-cutting techniques have proved most successful? Share your knowledge, and let’s keep the discussion on how to make PCB assembly more reasonably priced and quick for every sector of business.